The constant rise of the global electric vehicle market demonstrates two major trends: an increase in the number of consumers who choose electric vehicles and a diverse variety of electric vehicle types. Because of the increased demand, manufacturers are developing and manufacturing new electric vehicles.

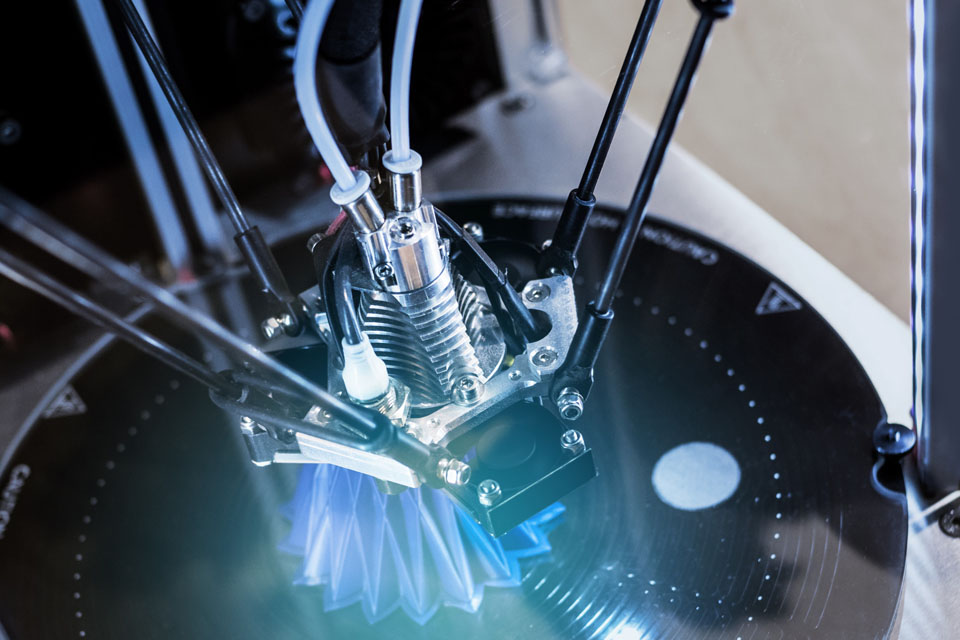

However, some issues must be addressed for manufacturers to create and build electric vehicles. Electric car manufacturers employ cutting-edge technology to overcome typical design and development issues. The use of additive or 3D printing technologies and similar battery technology assists manufacturers in addressing some of these critical issues.

Leading electric car factories prefer 3D printing to be conventional or subtractive manufacturing processes since it lessens the time to market and prices. Furthermore, major automakers invest in research and development to find ways to make 3D printing a seamless part of the EV manufacturing process.

Similarly, many producers are focusing on using 3D printing instead of subtractive manufacturing to overcome the challenges of producing electric vehicles. So, based on creative use cases and research projects, we can speculate on how 3D printing may impact the electric vehicle industry.

How 3D Printing Affects Electric Vehicle Manufacturing

Increased Market Time

According to recent research, the transition to electric cars is taking longer than expected. Many of the same companies that make regular cars also make electric vehicles. As a result, they are searching for methods to produce fewer EVs to fulfill the market’s existing demands. A corporation cannot reduce costs using conventional manufacturing processes unless it produces many electric automobiles.

However, 3D printing allows EV production in small quantities and as needed. Even though the number of automobiles produced remains low, neither the price per unit nor the number of rounds rises. The decrease in modifications allows manufacturers to bring their goods to market quicker while keeping prices down.

EV Personalisation

Car producers can’t sell more EVs without making them match each customer’s desires in this era of customizing and personalizing items. According to many, one of the most appealing aspects of 3D printing is its ability to be customized.

Engineers may customize the digital 3D model of a 3D-printed electric car (EV) to each customer’s preferences and interests. Companies can swiftly produce customized EVs for consumers since they do not need to purchase costly machine equipment, and the manufacturing process is faster.

Design adaptability

Unlike conventional manufacturing methods, 3D printing allows engineers to create items with complex forms without requiring additional time and effort. They can use 3D modeling software to create complex designs and 3D printers to transform them into actual pieces.

Furthermore, 3D printing enables them to enhance complex parts by thoroughly examining them and correcting design flaws. Engineers are now using 3D printers to test items by creating samples and to enhance parts by modifying how they are constructed.

Increased battery life

Creating batteries that live longer is one of the most difficult aspects of creating EVs. Automotive businesses invest in R&D to build better reusable batteries that will help sell more electric cars (EVs). 3D printing, like numerous battery technologies, may extend the life of EV batteries in various ways.

Engineers may utilize 3D printing to create new components and pieces that lower an EV’s weight and increase battery life. They can also produce lighter EVs by merging components. At the identical time, engineers may 3D-print heat vents and casings that regulate temperatures to extend battery life.

Digital warehouses

Traditional retailers not only raise operating expenses but also delay EV production. However, no automaker can produce EVs using conventional production methods without thinking about how to store and transport components and spare parts.

3D Printing assists automotive businesses in overcoming this difficulty by replacing physical warehouses with digital warehouses. Engineers can create 3D-printed items in days using computer 3D models. An automobile firm may employ 3D printing to create components on demand, eliminating the need for stock and storage space.

It may also make it simpler for engineers to produce spare parts by providing internet access to the digital 3D model. As a result, 3D printing allows the EV supply chain to be more adaptable by reducing wait time and expenses.

Material Options

According to tech journalists, one of the primary issues with 3D printing for mass manufacturing is that there aren’t enough materials to pick from. However, manufacturers can now select from various traditional and modern 3D printing materials.

They can create lightweight pieces out of various materials using 3D printing techniques. Similarly, they may increase the EV’s speed, power, and safety by employing 3D printing technology to create metal components.

Leading automakers now create components for 3D printing that have the necessary mechanical properties. Companies that provide 3D printing services enable EV producers to test a broad selection of materials on demand.

The emergence of 3D-printed electric automobiles

In 2022, XEV, a new company that creates one-of-a-kind electric vehicles, unveiled the YOYO, a 3D-printed electric vehicle. Since 3D printing eliminates the requirement for costly machine tools, XEV may be sold for around €10,000 in Italy.

Buyers may already pick from various 3D-printed electric vehicles, such as the YOYO. By 3D-printing EVs, YOYO will inspire electric vehicle manufacturers to streamline manufacturing processes, allow on-demand production, and simplify customizing their products.

Research Collaborations

Hyundai Motor Corp collaborated with academics on collaborative research projects in 2021 that employed Industry 4.0 technologies such as 3D printing and artificial intelligence to revolutionize the way automobiles are manufactured. The researchers will explore methods to utilize 3D printing in EV production. Buyers can customize EV vehicle models and auto components as part of the initiatives.

Conclusion

3D printing is the way that Business 4.0 is revolutionizing the EV industry throughout the globe. 3D printing processes help manufacturers reduce wait times and manufacturing costs and may even be used to make electric automobiles. Top automakers have been spending on research and development to make 3D printing a key aspect of creating EVs shortly. They will continue to 3D-print electric cars (EVs) to provide new models without increasing expenses upfront or over time.